This is probably the cheapest DLP SLA 3D printer that you can build yourself for some 500 USD including the projector!

"Little Dipper" has a simple design that anyone can replicate with some basic DIY skills and it makes prints with reasonable quality.

The most expenisve par is the projector which you can get dfor some 350 USd new, but you could probably get it used somewhere. Other parts include simple z axis movement (screw or belt driven) on wood frame and Ramps 1.4 or Arduino controlled electronics.

|

| Simple plastic vat and z axis screw drive |

|

| Objects 3d printed on Little Dipper |

|

| Objects 3d printed on Little Dipper. You can see the layers, but the quality is still great for the price. |

|

| Objects 3d printed on Little Dipper |

|

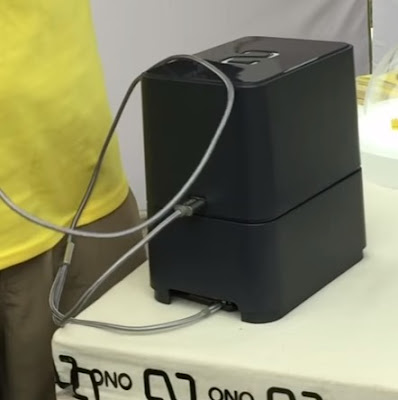

| Little Dipper DIY DLP Sla 3d printer. You can see all the elements with DLP projector on top. |

Here is the project description from the makers:

How it works?A DLP projector is used to cure UV setting resin one layer at a time while a moving axis drops incrementally into the vat of resin. A projected slice cures each layer and builds the part. This style of resin printer is different from a FormLabs 3D printer and some others in two ways.

- It uses a DLP projector rather than a laser to cure each layer.

- It shines the light source from the top rather than up from the bottom.

Advantages over laser based bottom up and DLP bottom up designs:- Simplicity

- Lower start-up cost

- Modifiable to bottom up

- Fast build (~1 evening)

Major Components and Materials:

DLP projectorThere are 2 known choices, although others may work.

- Acer P1283 DLP Projector

- Acer H6510BD DLP HD projector

Linear Slide/Axis

Almost any linear axis that is belt driven or screw driven will work. Project uses a minimal version of this:

http://www.openbuilds.com/builds/v-slot-lead-screw...A more budget minded and adventurous person could even choose a drawer slide, but you may find that rigidity and smooth sliding in the z-axis will be a useful feature.

4x4 sheet of 1/2in MDF or equivalent material and hardware

The version shown here is as simple as it gets. 2 pices of MDF cut to provide a mount for the axis, projector and stable footing for the machine. Pretty much any kind of enclosure can be designed for this 3D printer. Your main objective is frame rigidity and ambient light blocking.

Ramps 1.4 or Arduino based electronics capable of running at least (1) nema 17 stepper motor

This build features a RAMPS 1.4 board, stepper drivers and an Arduino Mega 2650 with standard Sprinter firmware. There are some basic modifications needed depending on the hardware you choose. None of these modifications constitute needing to know anything in-depth about programming. The firmware used is modified for 5/16 standard threaded rod and has end-stops disabled. You can modify this firmware using the Arduino environment to further suit your needs.

UV Resin

Makerjuice.com, Madesolid.com are the two most seemingly popular and affordable options for UV resin suitable for DIY resin printers such as the one featured in this build. This build has been tested with G+ from Makerjuice. Funtodoo, Form1+ and

Spark/Ember resin formulations are likely suitable.

Build Platform and Plastic Tupperware vat

This build includes plans for a build platform that fits a specific set of Tupperware available at "wallyworld". The benefit to the type chosen in this build is that you get a variety of sizes that scale easily, so that extensive design modifications are not needed. You will also need additional containers for post-cure/clean up of your resin parts.

Control Software and Slicer