Une avant-première pour les clients internationaux qui les découvriront lors des salons IMTS (US) et AMB (Allemagne)

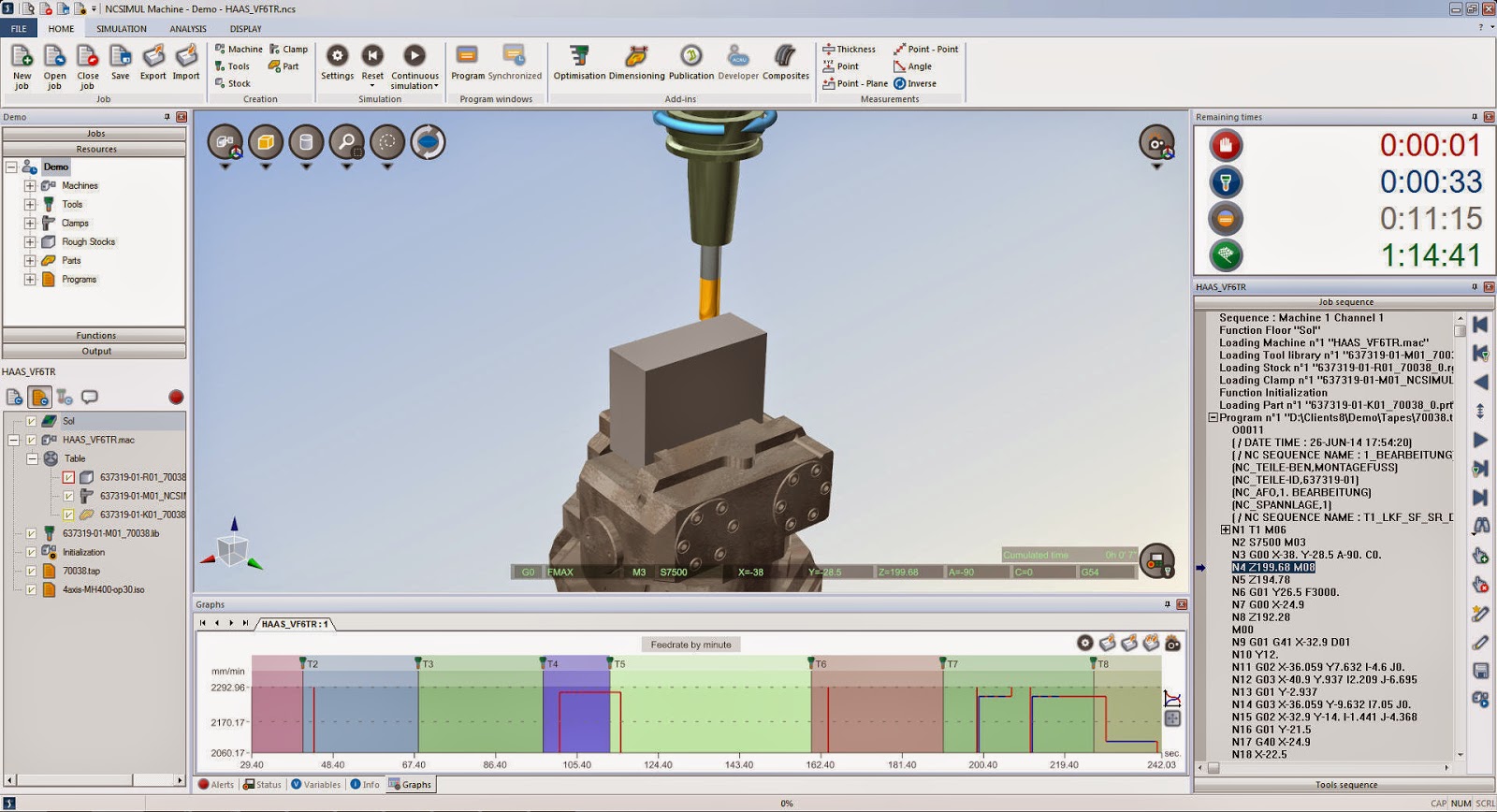

SPRING Technologies, éditeur de logiciels pour une utilisation optimale et flexible des Machines à Commande Numérique, annonce le lancement des WorkPackages CAM, interfaces entre plusieurs FAO du marché et NCSIMUL 4CAM (anciennement NCSIMUL CAM). Dans un premier temps, les visiteurs de IMTS (du 12 au 15 septembre à Chicago) et d'AMB (du 13 au 17 septembre à Stuttgart), pourront découvrir sur le stand de l'éditeur les WorkPackages pour : CATIA – Dassault Systèmes ; NX – Siemens ; CREO – PTC ; TopSolid'Cam – MISSLER et Mastercam, de la société éponyme. A terme, SPRING Technologies offrira à ses utilisateurs des interfaces directes avec les principales FAO du marché.

Pourquoi un WorkPackage CAM ?

NCSIMUL 4CAM est une solution puissante et novatrice, complément indispensable des FAO pour rendre son agilité à la production. A ce titre, elle doit permettre à ses utilisateurs de récupérer totalement et de façon transparente, leurs projets FAO pour changer de machine à commande numérique (CN) rapidement et facilement, et ce, sans reprogrammation aucune, grâce aux WorkPackages CAM notamment.

Dans le détail, NCSIMUL 4CAM donne aujourd'hui la possibilité au programmeur, quel que soit son secteur d'activité, de récupérer l'assemblage de sa pièce, son système de bridage, son modèle de brut, ses repères d'usinage et de positionnement, sa bibliothèque d'outils coupants associée et ce, directement et aisément, sans avoir besoin d'intervenir de nouveau sur la programmation du parcours d'usinage. En plus des fichiers ISO, le WorkPackage CAM permet, également, de lire les APT suivants : CATIA, Esprit, GO2CAM, NX, Pro-E, Surfcam, pour découper automatiquement les différentes phases d'usinage, afin de faciliter le changement vers la nouvelle machine. Une sécurité et un gain de temps non négligeables pour changer de CN, en fonction des impératifs de production et de la disponibilité du parc machines.

Une flexibilité primordiale pour la compétitivité des usines d'aujourd'hui et de demain.

Les bénéfices clients en quelques points

- Optimiser leur flexibilité pour adapter leur fabrication à la disponibilité de leur parc machines ;

- Augmenter les cadences et le TRS des machines CN ;

- Sécuriser les changements machines en un clic en générant un nouveau programme CN simulé, vérifié, optimisé et validé, quelle que soit la machine à commande numérique avant et après ;

- Suivre toutes les modifications effectuées suite au changement de machines dans les différentes séquences d'usinage ;

- Capitaliser le travail du programmeur par une reprise automatique des informations venant de la FAO ;

- Gérer et exporter les bruts intermédiaires en dynamique, pour une vérification instantanée des données tout au long de la phase d'usinage.

NCSIMUL CAM devient NCSIMUL 4CAM... Pourquoi ?

« Pour marquer de façon précise et sans ambiguïté le positionnement de notre produit, qui est un complément des FAO et non une FAO de plus, » affirme Gilles Battier, PDG de SPRING Technologies. « Nous connaissons nos points forts et nous les mettons en œuvre pour offrir des innovations technologiques à nos clients, et non un ersatz de solution déjà existante sur le marché. Notre objectif est, encore et toujours, de rester à l'écoute de leurs besoins pour les aider dans leur démarche vers l'Usine 4.0. »

_En.jpg)