This is the second stand of a two part commission (the original stand can be seen

here).This stand accommodates five guitars, one of which faces forward. The others lean left and right.

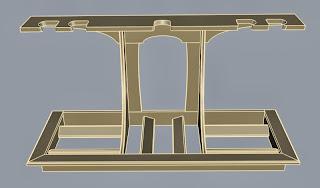

Here's the computer model:

The wood on all the most prominent surfaces is some fantastic, spalted tiger maple. The rest of the wood is also nice tiger maple - but not spalted. Once the stain (Minwax Golden Oak) hits the wood it helps to even out the spalting color with the result of even more intense figure.

Here are some progress pictures. The top, arch beneath the top, and curved supports were all cut on the CNC. The 5-axis was used for the top as the guitars rest against a 15 degree sloped surface.

The wood was twisted just enough that vacuum pressure could not hold it flat. So it was C-clamped to a sheet of MDF which was held to the table by vacuum.

Here's a short

You Tube video of the top being cut.

The supports were also CNC cut - mainly because its so easy to get a perfect curve.

My good friend Bob Ongaro helped me with the leather work for the surfaces where the guitars rest. Laying out patterns:

Here are two strips for the bottom supports. Usually we could get one bottom and one neck support from each strip.

Below is the pattern (in white) on top of some permanent double-sided carpet tape which adheres the leather to the wood. The curve of the pattern exactly matches the curve over the 15 degree taper to the neck pocket. Since that's a swarf cut it's a developable surface. So that's a perfect use for the Rhino UnrollSrf command to generate the pattern.

Finished: