I had some time to play around with ViaCAD and it looks really interesting. I've downloaded the 14-day trial version and used a few simple daily tasks to see how it performs.

First steps in the program interface are very easy and you are greeted with a simple video tutorial on how to create a 3D goblet from 2D drawing in 60 seconds:

From the beginning, I wanted to focus on 3D printing tools which are a part of this CADs features.

The toolbar with 3D Printing tools can be activated in the "Window" menu.

The interface is fast and fluid.

You can define your printer settings from a list of the pre-defined machine or set it manually:

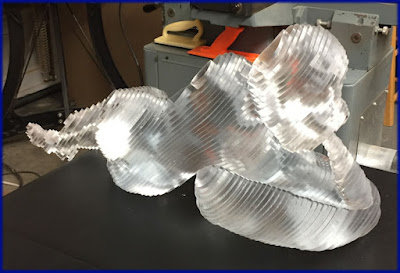

To see how other functions work, I imported the Voronoi "Broken benchy" by T-E-C from Thingiverse. It is a more complicated and harder version of the standard Benchy.

You can check the printability of your model with "3D Print Check" tool. Here is the output screen with some of the errors found, with several being my mistakes of not properly aligning the object or setting the parameters correctly (like print volume).

Very useful!

"Surface normals" tool shows, you guessed it, surface normals :-)

There are tools to show overhangs and wall thickness.

"Slices" tools will show animated slices base on several parameters, they can be saved into several formats. This is not a slicer which generates g-code for printing.

"Support structures" tool enables you to create support pieces and attach them with a mouse click.

With the "Position" tool you can place the object anywhere in selected print volume coordinate manually or with the automatic positions like "Center".

These basic tools were easy to use at this level, time will show how they perform in everyday work during a longer period. For now, I'm satisfied with this CAD software and will continue to us it.

You can get ViaCAD here and test it yourself and download a trial version from PunchCAD homepage:

PunchCAD.com

There are additional 3D Printing "power packs" for ViaCAD with 70+ 3d printing tools, you can see them here:

Punch! PowerPack v10

Here is a video demo:

Maybe I'll get them also in the future. The pack seems to have many tools in one place instead of using multiple apps and sites.

In next post, I'll describe some of my experiences with actual design and learning curve.

First steps in the program interface are very easy and you are greeted with a simple video tutorial on how to create a 3D goblet from 2D drawing in 60 seconds:

From the beginning, I wanted to focus on 3D printing tools which are a part of this CADs features.

The toolbar with 3D Printing tools can be activated in the "Window" menu.

The interface is fast and fluid.

You can define your printer settings from a list of the pre-defined machine or set it manually:

To see how other functions work, I imported the Voronoi "Broken benchy" by T-E-C from Thingiverse. It is a more complicated and harder version of the standard Benchy.

You can check the printability of your model with "3D Print Check" tool. Here is the output screen with some of the errors found, with several being my mistakes of not properly aligning the object or setting the parameters correctly (like print volume).

Very useful!

"Surface normals" tool shows, you guessed it, surface normals :-)

There are tools to show overhangs and wall thickness.

"Slices" tools will show animated slices base on several parameters, they can be saved into several formats. This is not a slicer which generates g-code for printing.

"Support structures" tool enables you to create support pieces and attach them with a mouse click.

With the "Position" tool you can place the object anywhere in selected print volume coordinate manually or with the automatic positions like "Center".

These basic tools were easy to use at this level, time will show how they perform in everyday work during a longer period. For now, I'm satisfied with this CAD software and will continue to us it.

You can get ViaCAD here and test it yourself and download a trial version from PunchCAD homepage:

PunchCAD.com

There are additional 3D Printing "power packs" for ViaCAD with 70+ 3d printing tools, you can see them here:

Punch! PowerPack v10

Here is a video demo:

Maybe I'll get them also in the future. The pack seems to have many tools in one place instead of using multiple apps and sites.

In next post, I'll describe some of my experiences with actual design and learning curve.