Two weeks ago I posted about

BEA Systems drones with internal 3d printing. In that post I wrote:

I also have slight suspicion that someone will want to 3d print bombs on-board of military aircraft. Still, all limitations remain. Why send something very expensive and heavy when you have proven delivery methods? Maybe some tactician is thinking of highly customized munition for very demanding missions with uncertain parameters for high-value targets.

Today I found put in article by

Vice that this technology is actually in practical development:

“3D printing of warheads will allow us to have better design control and utilize geometries and patterns that previously could not be produced or manufactured,” James Zunino, a researcher at the Armament Research, Engineering and Design Center (ARDEC) in Picatinny, New Jersey, told Motherboard in an email.

The ability to print parts previously unimaginable using traditional manufacturing methods could radically open up the possibilities when it comes to what a warhead can do. For example, warheads using 3D-printed components could be designed to be more compact in order to pack in additional payloads, sensors, and safety mechanisms. Planning for printed parts in the design process will also allow the army to precisely engineer the blast radius of warheads for maximum effect.

“Warheads could be designed to meet specific mission requirements whether it is to improve safety to meet an Insensitive Munitions requirement, or it could have tailorable effects, better control, and be scalable to achieve desired lethality,” Zunino wrote.

As an organization with a shrinking budget—except when it comes to drones—the army weighs the cost of human life against that of building the instruments of its eventual liquidation. One cross-industry advantage of 3D printing is its cost-effectiveness since it enables the printing of complex structures in one go, instead of the many individual parts that go into it. Missiles are no different.

“3D printing also allows for integrating components together to add capabilities at reduced total life cycle costs,” Zunino explained. “It is expected that 3D printing will reduce life-cycle costs of certain items and make munitions more affordable in the long run through implementation of design for manufacturability, and capitalizing on the add capabilities that 3D printing and additive manufacturing can bring to munitions and warheads.”

The army doesn’t plan on stopping at merely printing warhead components, either. Eventually, they want to print the whole damn thing in one go. “Maybe someday an entire warhead or rocket could be produced as the technology further matures,” Zunino wrote.

BEA Systems wanted this type of technology by 2040, but it looks like there will be 3d printed warheads much sooner.

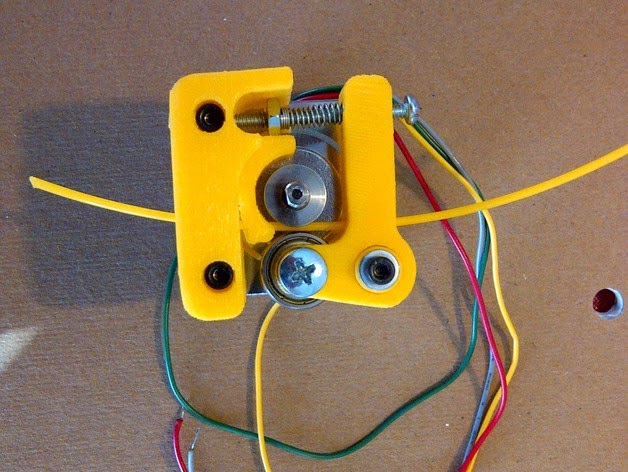

I searched around and found an DIY project where someone 3d printed plastic sabot round on a Makerbot to be fired from homemade combustion cannon. The future will be very interesting.

In reality, the actual 3d printed warhead will probably look something like this:

|

Rytheon STM, source: http://weapons.technology.youngester.com/2011/04/new-warhead-small-tactical-munition.html

|

It is Rytheon's Small Tactical Munition, a new weapon specifically designed to be employed from unmanned aircraft systems. STM is a 13 pound guided munition that is approximately 2 feet long, making it the smallest air-launched weapon in the Raytheon portfolio. It has a 5 pound warhead. It is small, light and lethal and enables drones to fly longer, further and attack more targets.

So, it is possible that there will be small 3d printing factories in forward military air bases that will create munition similar to this, cutting the cost, reducing the need for supply lines and making custom munition for any purpose like anti personnel with more fragmentation, material penetration with more mass, anti-armor with shaped charges. For those small drone bombs plastic materials could be used or even locally sourced materials. Only non-printable parts are currently guidance unit, explosives and fuse.

Those digital fabrication production cells could also make replacement parts for the drones themselves.

War is hell people, we need more food and less bombs.