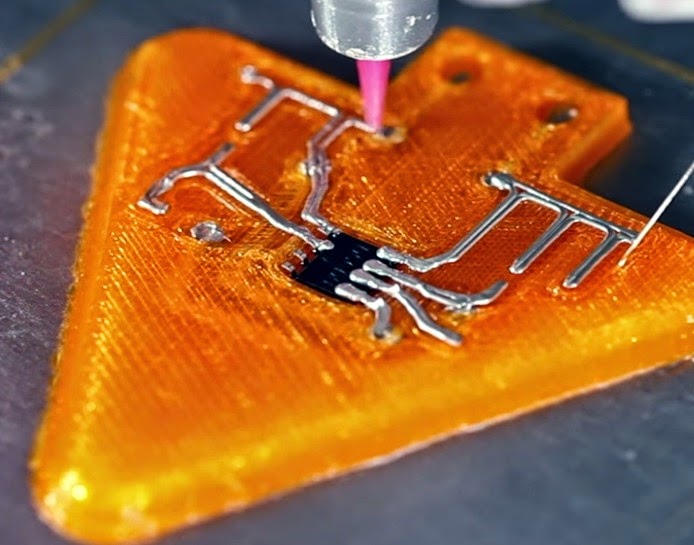

Disney researchers developed a 5 axis 3d printer that can also lay metal wire for electric and electronic devices. Wires can be fixated by extruding plastics on it. Since it moves in 5 axis, it can make overlapping wire coils and other intricate geometry objects.

Project description by Huaishu Peng:

We introduce a new form of low-cost 3D printer to print interactive electromechanical objects with wound in place coils. At the heart of this printer is a mechanism for depositing wire within a five degree of freedom (5DOF) fused deposition modeling (FDM) 3D printer. Copper wire can be used with this mechanism to form coils which induce magnetic fields as a current is passed through them. Soft iron wire can additionally be used to form components with high magnetic permeability which are thus able to shape and direct these magnetic fields to where they are needed. When fabricated with structural plastic elements, this allows simple but complete custom electromagnetic devices to be 3D printed. As examples, we demonstrate the fabrication of a solenoid actuator for the arm of a Lucky Cat figurine, a 6-pole motor stepper stator, a reluctance motor rotor and a Ferrofluid display. In addition, we show how printed coils which generate small currents in response to user actions can be used as input sensors in interactive devices.

You can see it in action here:

project homepage with more information:

http://www.huaishu.me/projects/electromagnet.html

While this project looks interesting, wire deposition with 3d printer head is not new in DIY world. Spoolhead was a RepRap project in early 2010 that did something simillar.

SpoolHead homepage:

http://reprap.org/wiki/SpoolHead