I've been further experimenting with the rotary axis on my router this week. The first goal was to produce a small head sculpture. The idea was to make a wood version of this sculpt I'd previously 3D printed. This is the result:

For the roughing of this block I used the 3/8" four-flute upshear endmill. I started with a step-down of 3/8" and a step-over of 1/4". That's very reasonable if the block was fixed to the table! Let's see how it went shall we?!

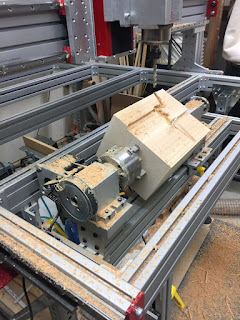

As before I glued on 2"x 2" plywood blocks to grip the stock:

Clamped in the head stock chuck it's ready to go.

It started fine but during a helix lead-in the upward pull of the endmill was too much for the rotary motor to hold - the block twisted and the bit gouged it. It was a high speed steel bit (which can handle more deflection than solid carbide) so no tool breakage. And the slash was into material that'd be removed anyway. So no harm done. Disappointing though ... the helix cut that caused it to give way wasn't even all the way towards the edge of the block. Hmmm...

I changed the roughing settings to a 1/4" step-down and 1/8" step-over. I also halved the plunge angle of the entry helix. This is a lot more gentle (and a lot slower!)

With that change the cutting went okay. This block is Basswood. Woodworkers know this cuts beautifully with gouges - a real pleasure. As you can see it's pretty fuzzy when cut on the endgrain with router cutters.

Here's the result after some quick sanding. It would need more to really refine it but I'm going to simply use this test to show my students the difference between roughing and finishing. Also the difference in surface quality between milling side grain and end grain.

Another problem with this large block... tool reach. In particular the length of the cutting edge of the 1/8" ball-end mill I was using. It has a 1" cutting length and a 3" overall length. Not adequate for the back of the head.

The tool extender shown in the image above can certainly help in some cases. But it's about 1" wide at the chuck. This width can be a problem when trying to reach down to near vertical surfaces to mill.

I have some tapered tools but there's an issue with the taper affecting the shape beyond the cutting tip.

The existing timing pulley worked fine on the new motor shaft. I just had to remove the key from the shaft before sliding it on and securing the set screws.

So far this feel much more solid. But more milling is required to really know.

I attended a workshop on Audoesk Fusion 360 software. I was impressed by the toolpath programming options available. I've been using Mastercam for years. But there's a lot to like about Fusion - and it's MUCH cheaper. I'm very interested in some of its toolpath options for quick roughing. They helix plunge the tool in much deeper and take repeated shallow, circular cuts. This is better than the parallel cuts I used because they engage more of the tool length. For finishing they have some nice toolpaths to deal with the change from mostly horizontal to mostly vertical surfaces. This is a problem with the parallel approach I used.

So that's where I'm headed next.

Milling a New Block - A Small Test

I started with a small block of Poplar, roughly 4" x 4" x 6". Poplar is really nice - huge trees so it's easy to get large, clear chunks of wood. I can get 16/4 (4" thick in the rough) near where I live. Poplar has a pleasing, subtle grain pattern. It's downside is the color (often a slight greenish cast with lighter sapwood). Staining can be used to make this more uniform and pleasing but applied to the raw wood it tends to be very blotchy. So sealing before staining is required.

Roughing happens with tools called end mills. These tool cut on the side of the tool as well as the end. They have sharp corners.

Finishing happens with ball end tools. These cut a curved bottom trough. Lowering the step over of each successive cuts makes the surface smoother and smoother.

These are the end mills I use:

Large Roughing: 1/2" 4 Flute Extra Long High Speed Steel End Mill

Medium Roughing: 3/8" 4 Flute Extra Long High Speed Steel End Mill

Fine Finishing: 1/8" 4 Flute Long Ball End Mill

Pencil: 1/16" 3 Flute Ball Nose End Mill

I also use this extender: Tool Holder Extension

The final side doesn't have much wood left!

Continuing to rotate to each side the final form becomes clearer:

That tool is tapered 1 degree. Even that small amount is problematic in this application. I'll use straight tool next time.

Here's the sculpt without the pencil cut yet - you can see the lack of definition in the eyes, nose and mouth:

I cut it a few times, quickly adjusting the Z0.0 point, with each pass going 0.01" deeper, until I got it looking the way I wanted:

Also of note is the extra material around the neck. This can't be easily reached using the depth I had set so it has to be removed by hand with carving tools. Some has been carved away already on one side.

Tools

The tools I used get divided into roughing (taking off large amounts of wood), finishing (taking the form from rough to smooth), and detail (drawing in fine detail). Roughing are at the top, finishing in the middle, and detail at the bottom. The lowest tool is an extender giving the tools a greater reach.Roughing happens with tools called end mills. These tool cut on the side of the tool as well as the end. They have sharp corners.

Finishing happens with ball end tools. These cut a curved bottom trough. Lowering the step over of each successive cuts makes the surface smoother and smoother.

Large Roughing: 1/2" 4 Flute Extra Long High Speed Steel End Mill

Medium Roughing: 3/8" 4 Flute Extra Long High Speed Steel End Mill

Fine Finishing: 1/8" 4 Flute Long Ball End Mill

Pencil: 1/16" 3 Flute Ball Nose End Mill

I also use this extender: Tool Holder Extension

Stock Preparation

The block was jointed on two perpendicular faces to make one reference corner where all the measurements could be taken from.

For the chuck of the head stock to grip the block you need a square chunk of material. These is easily done by gluing on small plywood blocks to the ends of the block.

Roughing

Here are some photos of the cutting process - roughing passes on all four sides. This is done with a 3/8" bit. Depth is 1/4", step over is 1/4". I left 0.1" of stock above the finished surface on the roughing passes.The final side doesn't have much wood left!

Finishing

The next step is smoothing passes over each side. Because of limited length of the flutes on the cutters and tool reach it is programmed to only go so deep (and thus so far laterally on each side). I used a 1/8" ball end mill.Continuing to rotate to each side the final form becomes clearer:

That tool is tapered 1 degree. Even that small amount is problematic in this application. I'll use straight tool next time.

Detail - Pencil Toolpath

The final pass, in this case done on just the face side, was a Pencil Toolpath. It automatically finds the crevices in the form and follows them. Here's the mesh surface in green with the tool path in cyan and the lead-ins and traverses in yellow.Here's the sculpt without the pencil cut yet - you can see the lack of definition in the eyes, nose and mouth:

I cut it a few times, quickly adjusting the Z0.0 point, with each pass going 0.01" deeper, until I got it looking the way I wanted:

Also of note is the extra material around the neck. This can't be easily reached using the depth I had set so it has to be removed by hand with carving tools. Some has been carved away already on one side.

Trimming and Carving

The sculpt has to be cut free of the support material at the top and bottom. The bottom is really useful for clamping in a vise so that's the last thing to go. First step is to band saw off the top support leaving enough to carve down to the hair:

A Larger Test

This next attempt was 10" long, 6.5" thick and 7.75" wide laminated from two pieces of 16/4 Basswood. Same 3D model just scaled up.For the roughing of this block I used the 3/8" four-flute upshear endmill. I started with a step-down of 3/8" and a step-over of 1/4". That's very reasonable if the block was fixed to the table! Let's see how it went shall we?!

As before I glued on 2"x 2" plywood blocks to grip the stock:

Clamped in the head stock chuck it's ready to go.

It started fine but during a helix lead-in the upward pull of the endmill was too much for the rotary motor to hold - the block twisted and the bit gouged it. It was a high speed steel bit (which can handle more deflection than solid carbide) so no tool breakage. And the slash was into material that'd be removed anyway. So no harm done. Disappointing though ... the helix cut that caused it to give way wasn't even all the way towards the edge of the block. Hmmm...

I changed the roughing settings to a 1/4" step-down and 1/8" step-over. I also halved the plunge angle of the entry helix. This is a lot more gentle (and a lot slower!)

With that change the cutting went okay. This block is Basswood. Woodworkers know this cuts beautifully with gouges - a real pleasure. As you can see it's pretty fuzzy when cut on the endgrain with router cutters.

Here's the result after some quick sanding. It would need more to really refine it but I'm going to simply use this test to show my students the difference between roughing and finishing. Also the difference in surface quality between milling side grain and end grain.

Another problem with this large block... tool reach. In particular the length of the cutting edge of the 1/8" ball-end mill I was using. It has a 1" cutting length and a 3" overall length. Not adequate for the back of the head.

The tool extender shown in the image above can certainly help in some cases. But it's about 1" wide at the chuck. This width can be a problem when trying to reach down to near vertical surfaces to mill.

I have some tapered tools but there's an issue with the taper affecting the shape beyond the cutting tip.

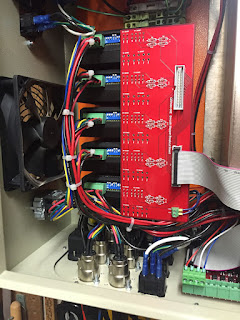

More Holding Power

Sooooooo... I think the holding power of the motor that came with the rotary kit was quite disappointing! I decided to replace it. The one that came with the rotary kit has a holding torque of 3.5N/m. The one I replaced it with has 6.8N/m - nearly twice as much. Here's a picture comparing the two (new one installed, old above it). The new one is longer and heavier and much better made. It uses 7 amps rather than 4.8 so I had to change the DIP switches on the motor controller in the electronics cabinet.The existing timing pulley worked fine on the new motor shaft. I just had to remove the key from the shaft before sliding it on and securing the set screws.

So far this feel much more solid. But more milling is required to really know.

Areas for Improvement

I want to have deeper holding blocks. 0.7" Baltic Birch plywood is not thick enough. The tools come too close to the head stock chuck. I had no collisions but it is nerve wracking. I'd also like to devise a way to re-register the block in the machine if I need to take it out for any reason.I attended a workshop on Audoesk Fusion 360 software. I was impressed by the toolpath programming options available. I've been using Mastercam for years. But there's a lot to like about Fusion - and it's MUCH cheaper. I'm very interested in some of its toolpath options for quick roughing. They helix plunge the tool in much deeper and take repeated shallow, circular cuts. This is better than the parallel cuts I used because they engage more of the tool length. For finishing they have some nice toolpaths to deal with the change from mostly horizontal to mostly vertical surfaces. This is a problem with the parallel approach I used.

So that's where I'm headed next.