The software processes 3x faster than the company’s previous simulation program

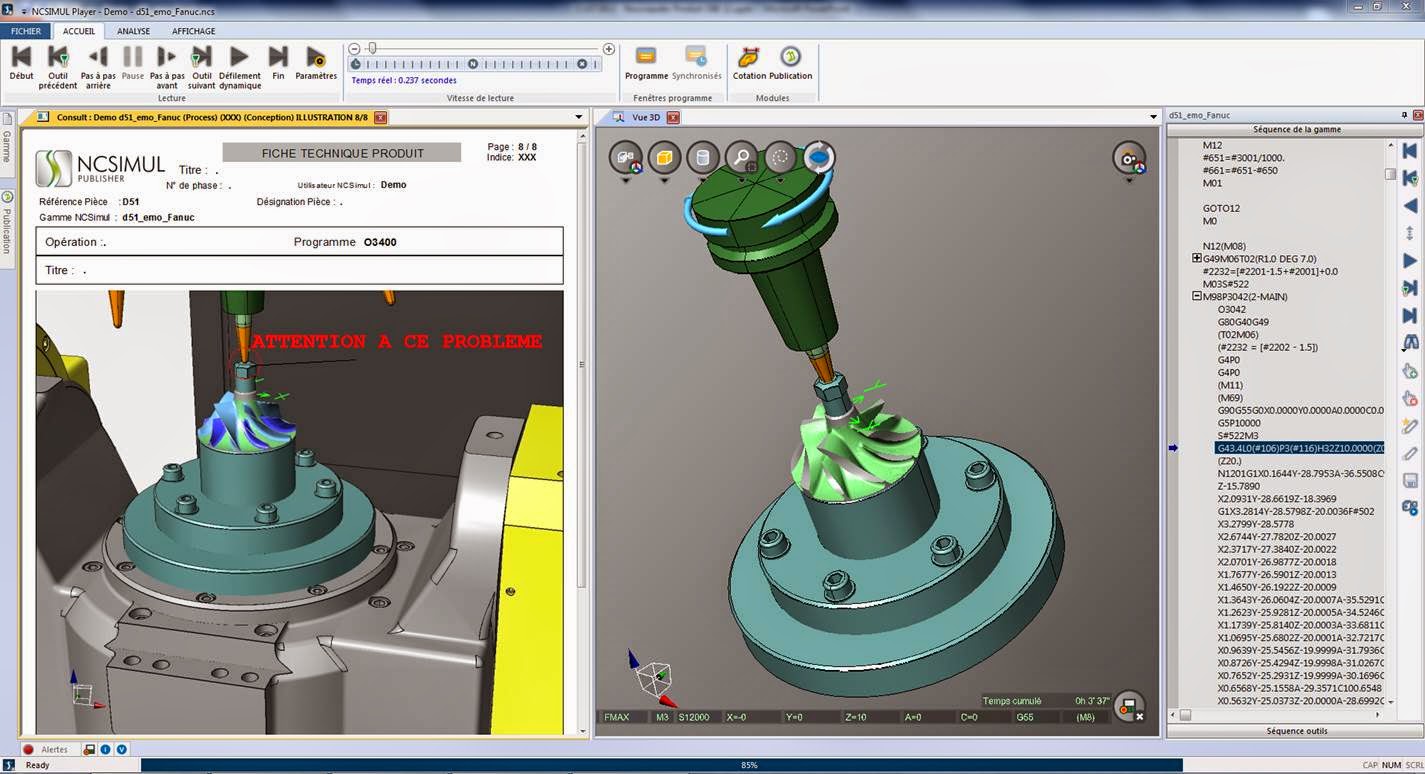

SPRING Technologies is pleased to announce that the engineering company Musashi, in Japan, has chosen to use NCSIMUL Machine software in its 5-axis operations. Before choosing NCSIMUL Machine, Musashi applied another NC simulation software package for the 5-axis machining process used to make turbine impellers. The operation took over 16 hours and the user interface froze frequently when rotating or zooming in on the 3D model during simulation. Musashi consequently set out to find a solution that would offer faster simulation, with smooth 3D model handling and easy settings.

“We wanted to run the simulations on our 5-axis impeller machining process faster. We were looking for an easy-to-use application and automated simulation software,” said Mr. Baba, manager of the Development Department.

At the time, Mr. Yagihashi, the president of Musashi, visited the Saeilo Japan booth at the JIMTOF 2012 tradeshow, where he first heard about NCSIMUL Machine.

“Our president visited many other booths to get an overview of the NC simulation products on the market. He asked to see NCSIMUL Machine, and was impressed by the great user-friendliness of NCSIMUL Machine interface.” said Baba.

Comparing NCSIMUL Machine with other NC simulation systems

- Machine / axis motion (machine simulation, collision check)

- NC program optimization (Auto-feed change)

- Comparison features (Incomplete cutting check)

- Multi-axis function (multi-access)

- Tool setting (interface)

- Machine (original MC environment )

For the complete story click here

.jpg)