Printeer is designed to be children frinedly 3d printer and to work in combination with simple iPad modeling application also fitted for young users.

Their Kickstarter campaign is going well since they have already reached funding goal with 20 more days to go. Check it out.

- A clear case prevents accidental contact with heated or moving parts.

- A removable build platform allows finished parts to be easily removed.

- Printeer uses PLA plastic filament, which is non-toxic and emits about 1/10th the ultra-fine particles of ABS plastic filament. (The same particulate emission as cooking food on low heat.)

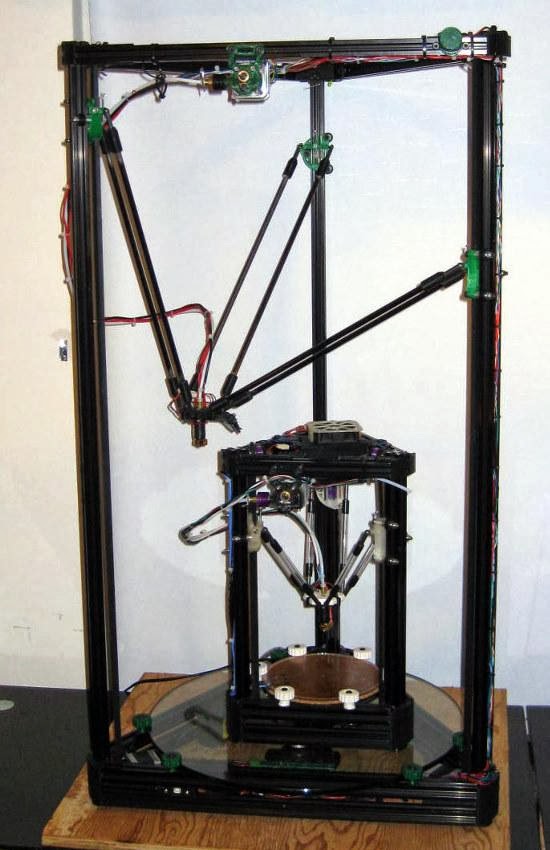

- Moving parts are visible so that kids can see how motors, pulleys, belts, and sliders work together to move a complex machine.

- Exterior dimensions: 16 inch (406 mm) wide x 9 inch (229 mm) deep x 12 inch (305 mm) high

- Build volume: 6 inch (150 mm) wide x 4 inch (100 mm) deep x 5 inch (125 mm) high

- Material: PLA plastic 1.75 mm filament

- Weight: 12 lbs (5.5 kg)

- Fully enclosed

- Removable print bed

- Auto bed leveling

- Wireless access

- Spool capacity: 1 lb (0.45 kg) of filament

- Built using a variety of open-source software & hardware

Printeer is on Kickstarter now where you can get it for 499$:

https://www.kickstarter.com/projects/2001363001/printeer-a-3d-printer-for-kids-and-schools

Company page:

http://printeer.com/