E3D is well known for their excellent hotends. Now they have released new model: the v6. v6 is next-generation full metal hotend for RepRap 3D printers.

|

| E3D v6 hotend |

v6 release video:

Here is v6 video review by Thomas Sanladerer:

How to assemble the v6:

v5 hot end was a success and lessons learned on it influenced the development of v6, Here are desgn guidelines by E3D:

- v5 is longer in the Z axis than many other hotends on the market due to significant safety margins in heat dissapation, screw in bowden fittings make bowden hotends even longer.

- Our printed fan duct is a little bulky in X/Y which can create issues when space under carriages is restricted.

- Make assembly and maintenance easier for the user.

- Securing thermistors with kapton works well, but is difficult to achieve easily and neatly, especially for the new user. It also makes changing out thermistors a bit time consuming. Cementing in thermistors with fire cement or similar works well, but is messy and difficult, it also makes changing thermistors nearly impossible.

- The printed fan duct is a bit tricky to remove as it has to be slid off the heatsink either up or down which can be tricky with wiring etc in the picture.

- Improve support for flexible materials.

- v5 works as well as any other hotend on the market for flexible filaments, however this inevitably means printing very slowly, getting messy prints and having to constantly battle with buckling in the extruder.

- Flexible filaments are entering the market and have some exceptionally useful properties and we want to enable more people to use them with a better printing experience.

- Shorten heat up times and increase accurate control of temperature.

- v5 uses a set screw to secure the cartridge which works well, but because of the slight variances in heater cartridges the hole in which the cartridge sits has to have some clearance to allow it to easily slide into place, this affects heat up times and control.

- Thermistor placement in v5 is close to the surface of the block, which makes things easier when your thermistor has to be insulated with kapton but this has some impact on the precision of the readings.

- Fix niggling reliability issues.

- v5 has a great track record of reliability with less than a fraction of one percent of users experiencing issues due to manufacturing issues, however we really wanted to eliminate any chance of future defects.

- 1.75mm Bowden users were experiencing a disproportionate amount of problems, which was traced back (with much help and hard work from Michael Hackney) to nozzle geometry in certain situations needing high extrusion pressures that resulted in starvation of filament flow.

- Make different sized nozzles more suitable for their application and each size more identifiable.

- All v5 nozzles share the same shape of tip that lays down the track of filament, we wanted to make the shape of each nozzle more suited to their particular use case and application so people can get the best results from each nozzle size.

- Because all nozzles share the same shape they are hard to tell apart, particularly when there is plastic residue remaining on the nozzle. We wanted to make it easy to differentiate between nozzles.

- Looks matter! Our machined metal parts look awesome, but with them hidden behind a printed fan duct you can't admire all that wonderful engineering.

|

v6 on the left compared to v5 on the right.

You can also see that the entire Bowden coupling is contained inside the heatsink on v6. |

v6 technical specifications:

- Compact size: v6 is now 62mm in overall length, and the new polycarbonate fan duct results in significantly less bulk in X and Y dimensions.

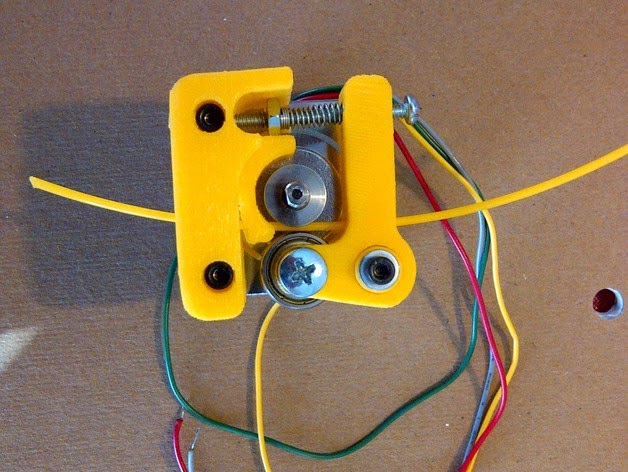

- Easy assembly and maintenance: All assembly is performed by either clipping or screwing together parts, no messy Kapton or adhesives are needed – The thermistor secures with a neat screw clamp and is insulated with high temperature glass fibre sleeving. Supplied ferrules mean that no soldering is needed.

- Fast heat-up and better temperature readings: The heater cartridge is secured with a wrap-around clamp for excellent thermal contact, this reduces warm-up times and increases temperature control. The thermistor has been placed deep into the block and near to the nozzle in a close fitting hole for the most accurate readings and fast response.

- Overhauled manufacturing techniques for increased reliability: The HeatBreak has a radically improved surface finish stemming from updated manufacturing techniques. The nozzle has been optimised for easier flow at low pressures.

- Improved performance with flexible materials: Internal PTFE tubing runs deep into the hotend and can be arranged so that flexible filaments are constrained in the PTFE tubing right from the drive gear to deep in the hotend. PTFE never enters hot areas and so high temperature capability is maintained.

- Maintains Compatibility: By keeping our previous mounting dimensions we have maintained compatibility with our plethora of community created mounting systems. Nozzles have kept their M6 threaded dimensions and so are interchangeable between v5 and v6.

- Universal 1.75mm HotEnd: The incredibly compact tubing coupling system that is internal to the hotend means that we are able to eliminate the 1.75mm Direct and 1.75mm Bowden products and replace them with a single 1.75mm Universal product.

|

| E3D v6 technical specifications |

Here are cross sections of three versions of v6: from left to Right: 1.75mm Universal, 3mm Direct, 3mm Bowden.

E3D v6 is priced at £43-£48 range for a kit and £31-£33 for metal hotend only.

E3D v6 release page with much more details:

http://e3d-online.com/index.php?route=extras/blog/getblog&blog_id=21